Contact Us

For all of your Vossen wheel enquiries please contact us at:

FUEL AUTOTEK

ADDRESS: 25/9 Hudson Avenue, Castle Hill NSW 2154EMAIL: enquiries@fuelautotek.com.au

For all of your Vossen wheel enquiries please contact us at:

Aggressive and unique designs comprise Series 17, where any and all ideas and concepts can become reality for nearly any vehicle, from an exotic hyper car to off-road truck application. The S17-12 wheel is designed to utilize an OEM Rolls Royce floating centre cap for Rolls Royce models as well as an all-new Vossen floating centre cap for any other applications. CNC machined in Miami to exact specifications for every vehicle application.

Wheel pictured in Dark Smoke.

The S17-12 wheel is designed to utilize an OEM Rolls Royce floating center cap for Rolls Royce models as well as an all-new Vossen floating center cap for any other applications.

| 8.5 | 9 | 9.5 | 10 | 10.5 | 11 | 11.5 | 12 | 12.5 | 13 | |

|---|---|---|---|---|---|---|---|---|---|---|

| 19" | ||||||||||

| 20" | ||||||||||

| 21" | ||||||||||

| 22" | ||||||||||

| 23" | ||||||||||

| 24" |

Vossen’s in-house finishing facilities utilize state-of-the-art equipment to produce only the highest quality finishes. From ceramic polishing to powder coating, all Vossen Forged wheels maintain industry-leading quality by monitoring ever step of the process with the utmost scrutiny.

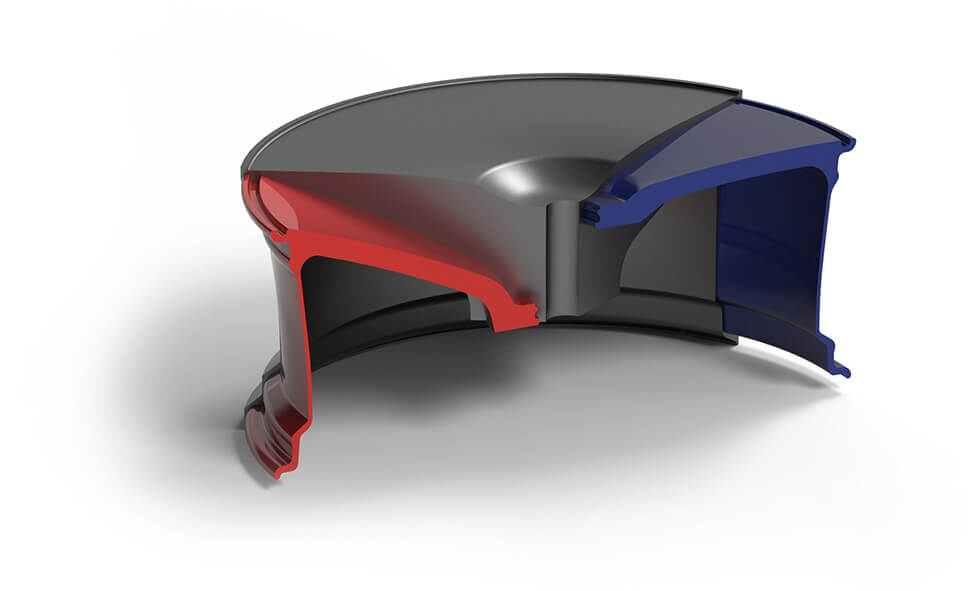

Learn MoreAll Vossen Forged wheels are machined using Vossen’s proprietary forging design. In order to provide any vehicle with the most efficient spoke profile, our forgings are engineered with extra material on the face in order to accommodate everything from flat to super deep concave profiles. This proprietary forging design allows us to produce an 8.5″ width with maximum concavity equal to that of a 12.5″.

| Vehicle Tailored Engineering | Vehicle-specific concave profile and FEA weight optimization | OPTIONAL |

| Lightening Pockets | Weight reducing pockets milled into the back pad of the wheel | OPTIONAL |

| Personalized Engraving | Wheel specifications, serial number and a personalized note on the inboard lip | OPTIONAL |

| Centre Lock | Design modified for centre lock application | OPTIONAL |

| Cap Finishes | Color matched to wheel with red ‘V’ shield | OPTIONAL |

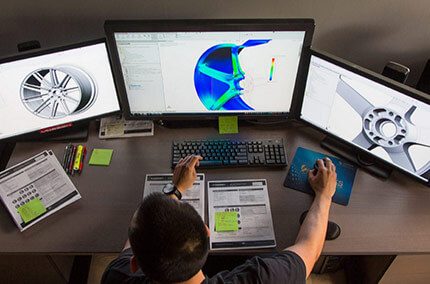

After three years of development, Vossen is proud to be one of the few companies in the world that manufactures forged wheels entirely in-house. Headquartered in Miami, Florida, USA, Vossen’s state-of-the-art, TUV-certified wheel manufacturing facility features a comprehensive array of brand new machinery.

Many forged wheel manufacturers utilize the simplest and most common machining techniques to increase productive volume. The Vossen Forged lineup, particularly the Precision Series, does not compromise its exclusive and complex features for manufacturing ease.

Precise fitments are achieved by taking measurements from over 100 different data points around the car. Those measurements lead to CAD models that are tested using Finite Element Analysis (FEA) to ensure SAE and TUV compliance while maximizing concavity. Each wheel is specifically made for each vehicle make and model.

Vossen Forged wheels utilize a manufacturing process developed to achieve the most uncompromising design and quality standards for forged wheels. In order to produce the most precise wheels in the industry, Vossen has developed a proprietary six-step machining process.

Manufacturing the best wheels in the industry begins with nothing but the finest raw materials, made in California. Vossen Forged wheels are made of aerospace-grade 6061-T6 aluminum forged into a proprietary forging design. Heat-treated for additional integrity, these monoblock forgings yield quality equal to and sometimes greater than the raw materials used by the world’s top OEM automakers.

Precision requires consistency and consistency requires control, which is why Vossen meticulously inspects every wheel during every step of the process. Vossen machinists conduct inspections on every wheel to ensure precision before proceeding to the next step.

The quality control team confirms every critical dimension according to detailed engineering schematics. Runout, a measurement of a rotating wheel’s roundness, is the most critical measurement. Vossen Forged wheels are checked to confirm that the runout is within tolerance.