Contact Us

For all of your Forgestar wheel enquiries please contact us at:

For all of your Forgestar wheel enquiries please contact us at:

DISCLAIMER: All Forgestar wheels are drilled to cone seat specs. Conical/tapered lug nuts will be required.

18″

8.0 to 14 inch widths available

19″

8.0 to 12.5 inch widths available

One modular profile is available

Forgestar’s Rotary Forged Flow forming process is a unique solution to a common problem – how to make a wheel both light and strong.

This specialized process begins with a low pressure type of casting and uses a special machine that spins the initial casting, heats the outer portion of the casting and then uses steel rollers pressed against the rim area to pull the rim to its final width and shape. The combination of the heat, pressure and spinning create a rim area with the strength similar to a forged wheel. During Flow Forming, the pressure applied to the cast rim actually changes its mechanical properties, so its strength and impact values become similar to those of a forged rim. That translates to up to 15% less weight when compared to a standard cast wheel. The resulting grain structure within the alloy of the wheel is linear, flowing in a single direction.

This grain structure pattern, combined with the exceptional quality of casting required for the process, gives the rim area of the wheel huge mechanical strength, and elongation. As a result of these mechanical characteristics, Forgestar is able to reduce the thickness of the rim area resulting in reduced weight, without compromising strength and resistance to impact.

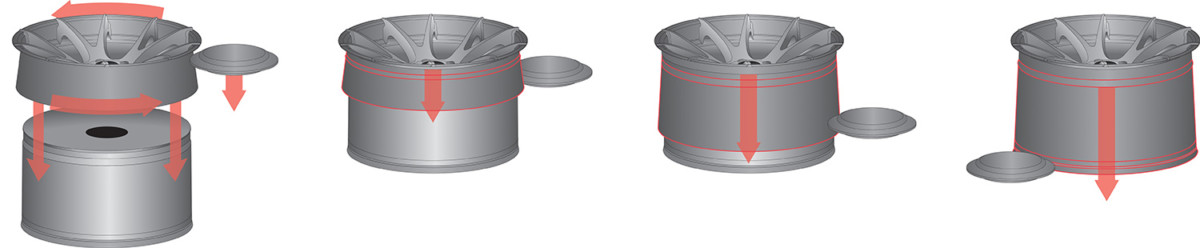

Rotary Forged Flow Forming process

The process begins with a specially designed casting that is spun while heating the outer portion.

Hydraulic rollers are used to form the barrel by applying heat and pressure.

As the rollers extend outward on the barrel the aluminum is stretched and compressed changing the mechanical properties and increasing the strength of the aluminum.

The final product is lighter, stronger with impact values similar to those of a forged rim.

Every new Forgestar Wheel starts off as design sketches. From the initial drawings designers are able to develop the product adding individual characteristics that will make each wheel an unique masterpiece.

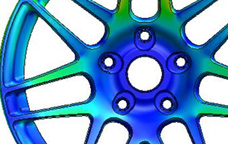

Once the basic design has been constructed using CAD software every detail of the development process can then be simulated and changed on screen. Using the latest 3D technology, developers can view and modify a realistic rendering of the actual wheel. All Forgestar wheel designs are then tested using Finite Element Analysis (FEA). The computer model enables engineers to analyze the design under a simulated load and optimize strength, fatigue, and stiffness while minimizing mass to decrease rotational inertia.

Once a new wheel is developed, the first prototype is heavily scrutinized and examined. During inspection it may be necessary to adjust, redesign or even discard the wheel design. After the final look and function is achieved the prototype will be subjected to strucutural testing.

Developing a new Forgestar wheel doesn't just involve creating a new design, it also means selecting proper finishes to match the unique and innovative construction elements. Forgestar custom powdercoats each set of wheel to each individual own taste. Powder coating is applied electrostatically and cured under heat to create a hard finish that is tougher then conventional paint.