Contact Us

For all of your Vossen wheel enquiries please contact us at:

FUEL AUTOTEK

ADDRESS: 25/9 Hudson Avenue, Castle Hill NSW 2154EMAIL: enquiries@fuelautotek.com.au

For all of your Vossen wheel enquiries please contact us at:

Available wheel finishes:

Custom Finishes

| Diameter | Width | Studs | PCD | Studs Alt | PCD Alt | Offset | Weight | Code |

| 19 | 8.5 | 5 | 112 | 42 | HF7-9M64 | |||

| 19 | 9.5 | 5 | 120 | 40 | HF7-9B64 | |||

| 20 | 9 | 5 | 112 | 32 | HF7-0M11 | |||

| 20 | 8.5 | 5 | 112 | 28 | HF7-0M05 | |||

| 20 | 10 | 5 | 112 | 50 | HF7-0M14 | |||

| 20 | 11 | 5 | 120 | 40 | HF7-0B14 | |||

| 20 | 9.5 | 5 | 114.3 | 25 | HF7-0N08 | |||

| 20 | 10.5 | 5 | 112 | 30 | HF7-0M17 | |||

| 21 | 10.5 | 5 | 112 | 35 | 0 | HF7-1M39 | ||

| 21 | 9 | 5 | 112 | 32 | 0 | HF7-1M34 | ||

| 21 | 12 | 5 | 120 | 52 | 0 | HF7-1B37 | ||

| 21 | 11.5 | 5 | 130 | 50 | 0 | HF7-1P34 | ||

| 21 | 9.5 | 5 | 130 | 53 | 0 | HF7-1P31 | ||

| 22 | 10.5 | 5 | 127 | 35 | 0 | HF7-2W44 | ||

| 22 | 9 | 5 | 112 | 32 | 0 | HF7-2M44 | ||

| 22 | 10 | 5 | 130 | 20 | 0 | HF7-2P71 | ||

| 22 | 9.5 | 5 | 130 | 53 | 0 | HF7-2P47 | ||

| 22 | 11.5 | 5 | 130 | 50 | 0 | HF7-2P50 | ||

| 23 | 10.5 | 5 | 130 | 25 | 0 | HF7-3P51 | ||

| 23 | 11 | 5 | 112 | 14 | 0 | HF7-3M51 | ||

| 23 | 10 | 5 | 120 | 32 | 0 | HF7-3B51 | ||

| 23 | 12 | 5 | 130 | 15 | 0 | HF7-3P59 | ||

| 24 | 10 | 5 | 130 | 15 | HF7-4P61 |

| Wheel Width | Offset(s) |

|---|---|

| 22 x 10" |

5x120 +32 5x130 +20 5x150 +35 Blank +6 |

| Wheel Width | Offset(s) |

|---|---|

| 23 x 10" |

5x120 +22 / +32 Blank +8 to +53 |

| 23 x 10.5" |

5x130 +21 / +25 Blank +15 to +60 Blank -20 to +25 |

| 23 x 11" |

Blank +21 to +66 5x112 +14 Blank -14 to +31 |

| 23 x 12" |

5x112 +14 5x130 +15 Blank -1 to +44 |

Concave Profile

Flat

Mid

Deep

Super Deep

The Vossen Hybrid Forged HF-7 is available in three different concave profiles. Flat, Deep and Super Deep profiles allow for extremely aggressive fitments for a wide range of makes and models.

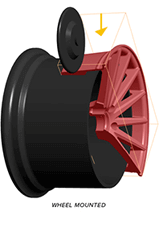

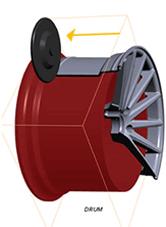

A cast wheel is mounted to the flow forming drum and heat is applied.

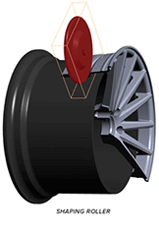

Hydraulic rollers stretch the wheel by applying pressure to to the barrel.

The wheel’s material is stretched and compressed to achieve the desired width.

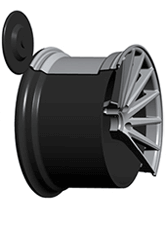

Stretching the barrel material improves the grain structure of the aluminum, making a stronger and lighter barrel, similar to a forged wheel.